Finally it’s time for reassembly – first of all the Sprocket!

Related posts:

These are the Tools:

- 1/4 HEX

- 1 7/8 NUT

- sprocket locking tool

- torque wrench

- fixed wrench

- angle protractor

- Loctite 243

- Loctite 271

Terms and conditions: All work at own risk, NO warranty in ANY case of damage!

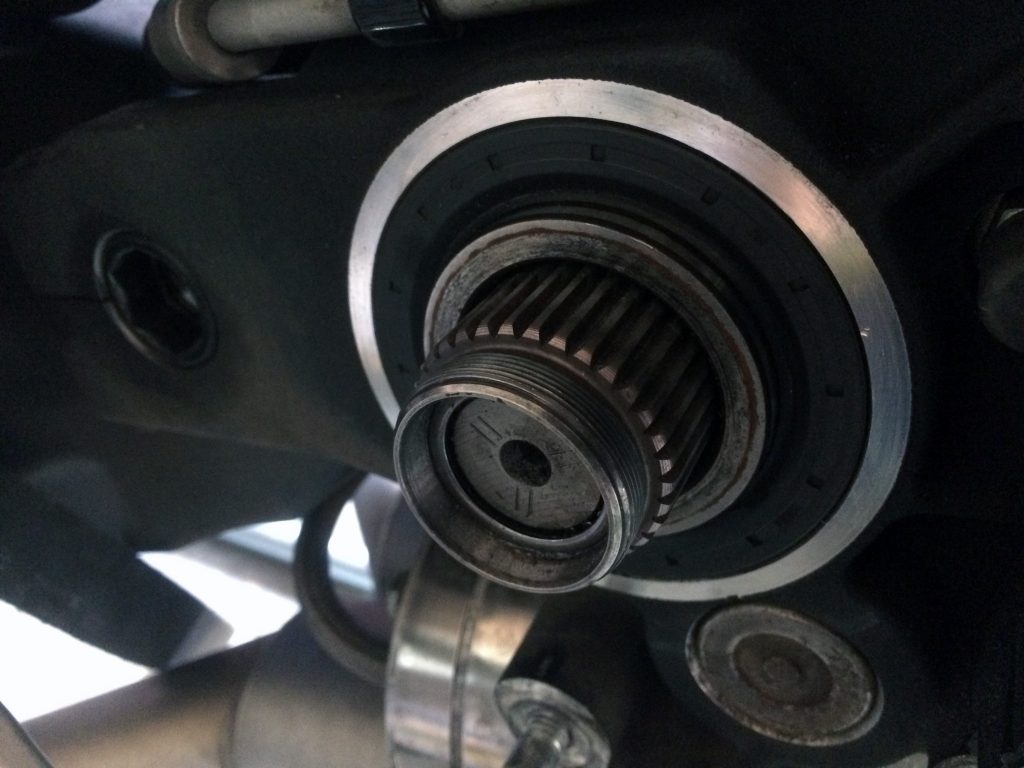

Step 1

First of all is to clean the thread, just with a brush. Then for the sprocket.

Step 2

Now you can install the locking tool for the right direction (left hand thread) and apply some Loctite 271 RED on the thread. In the same time I installed a new main shaft seal (HD 12030).

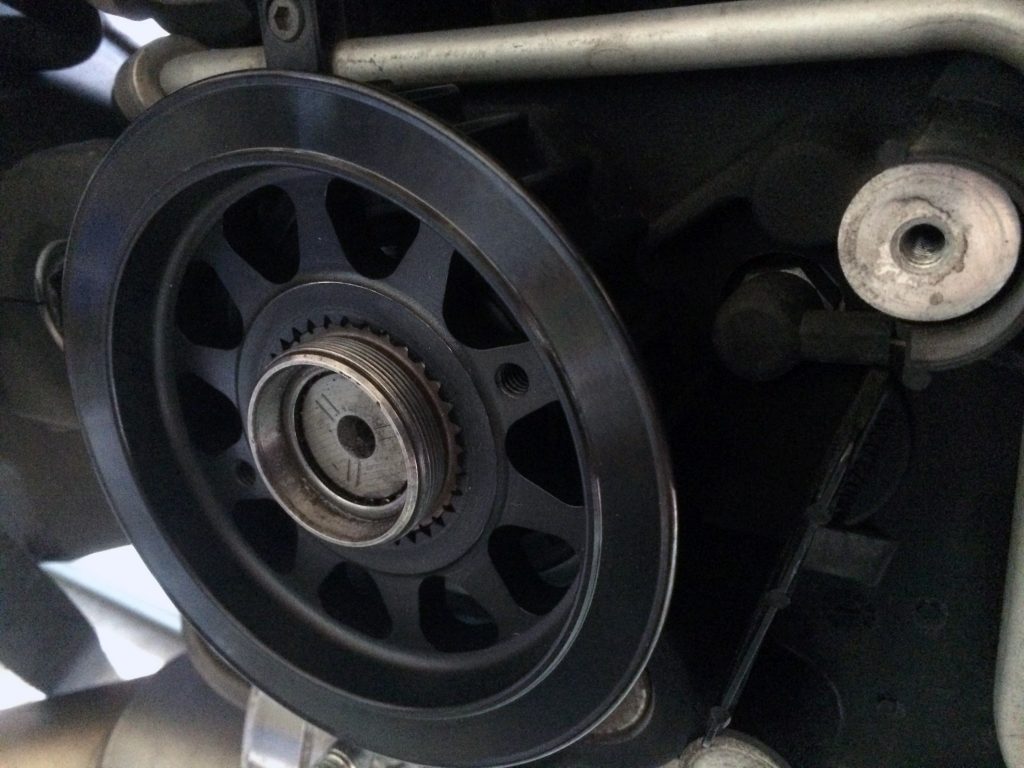

Step 3

Now set the torque wrench to left direction and do an initial 67,8NM on the 1 7/8 nut.

Step 4

After that change to a fixed wrench with the angle protractor installed and tighten the 1 7/8 nut counterclockwise an additional 30° – 40°. Mine is only for right handed threads so I tighten “backwards” from 30° to 350°. Note: Maximum allowable tightening is 45° counterclockwise. Never over tighten!

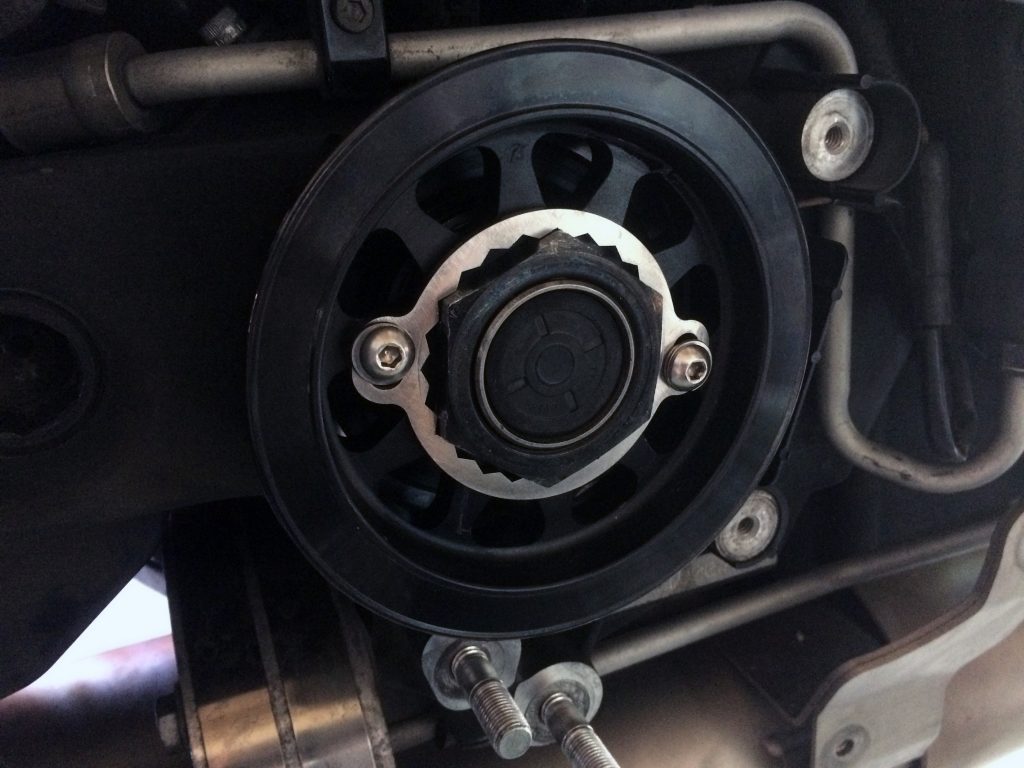

Step 5

After that act of hard work you can install the sprocket locking plate. I switched to a xborg custom in stainless steel with stainless steel screws (1/4 HEX).

Just apply some Loctite 243 on the screws and tighten them to 10,2-12,4 NM and your done.